TerraLam’s cross laminated design allows it to spread loads very efficiently in all directions while its larger footprint provides a greater area to disperse the load across. This translates to less pressure exerted on the ground while providing a more stable work surface.

ADD TERRALAM 300 TO YOUR PLASTIC SITES

Composite mats are newer innovations in the site access industry, offering great durability in a lightweight package. But as job sites require greater efficiency, Sterling presents an excellent opportunity to complement your composite mats with TerraLam 300 CLT mats. TerraLam is also a lightweight engineered product that has a solid top surface but offers more surface area per mat, a faster install, and a lower price point than composites.

TERRALAM VS COMPOSITE

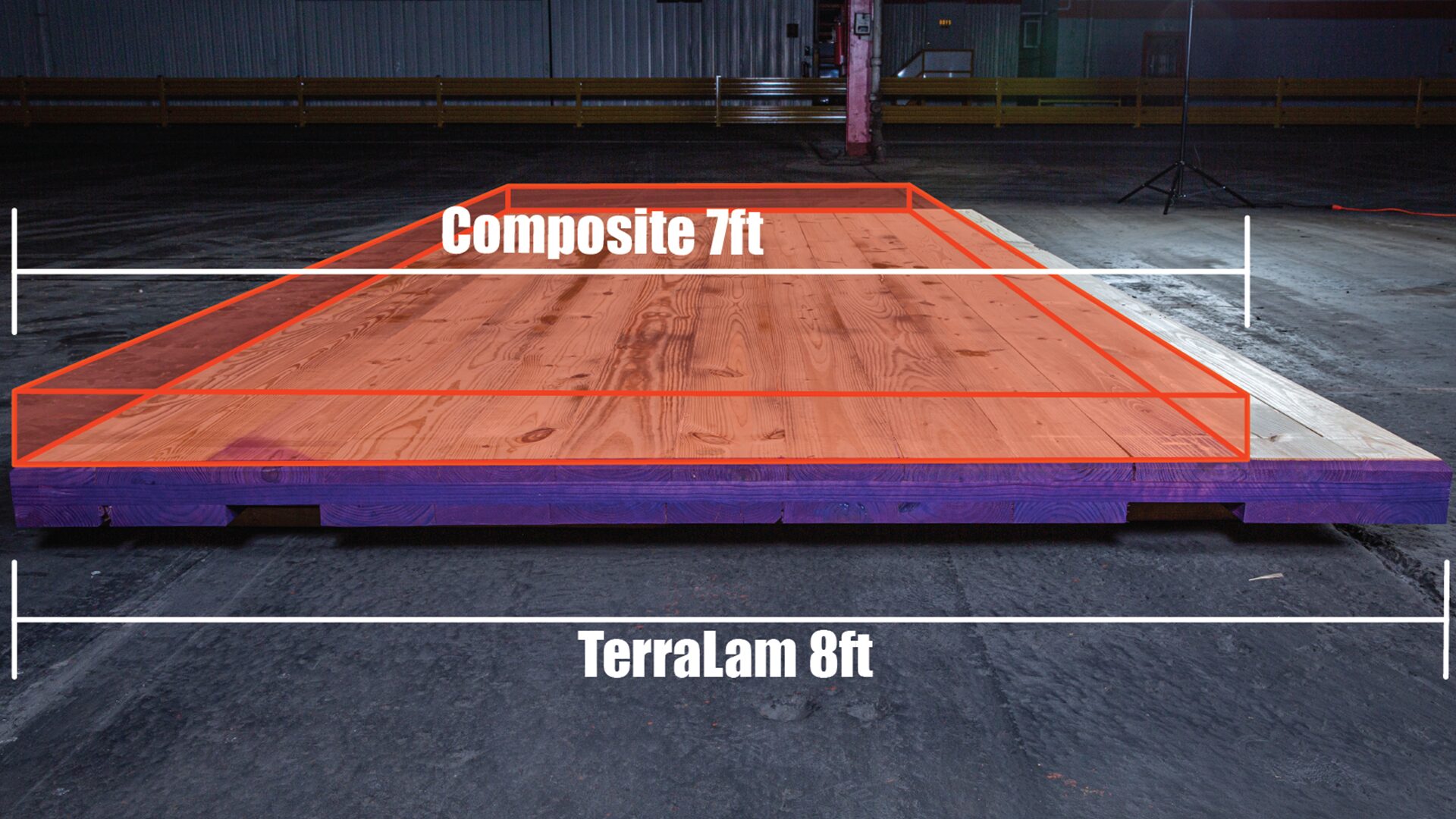

Increased Surface Area

Composite mats are lightweight but small. TerraLam mats provide much more usable surface area per mat compared to composites. Their larger design covers more ground, maximizing space for equipment and vehicles. This work pads are setup with less mats, getting you to work faster.

Superior Load Dispersion

Easier Installation

Composite mats often require multiple people to install but TerraLam mats can be installed by a single person, reducing the time and labor. This leads to huge labor cost savings, less exposure of on-site personnel to safety hazards such as moving equipment, and greater overall efficiency.

Connectable Mats

TerraLam mats don’t need to be connected like composite mats, but optional industrial grade straps can be installed to increase mat stability under certain conditions. These straps can be quickly installed by a single person using handheld power tools, away from moving equipment.

More Lineal Footage

TerraLam also gets more lineal footage per mat, meaning fewer mats are needed for longer distances. This reduces the total number of mats required for any Right of Way, minimizing handling and installation costs. TerraLams also provide a wider footprint to accommodate larger equipment.

Readily Available

TerraLam mats are made in Illinois and Texas using domestically harvested Southern Pine. These centrally located factories can each produce 1000 mats per day for even the largest projects. And because they are lightweight, transport costs are substantially lower than with other types of mats such as timbers.

Timber mats have their place—but there’s a better way to boost performance. See how adding CLT mats to your timber mat sites can enhance stability, reduce handling costs, and extend mat life. Discover how a hybrid approach can deliver stronger, safer, and more cost-effective results.